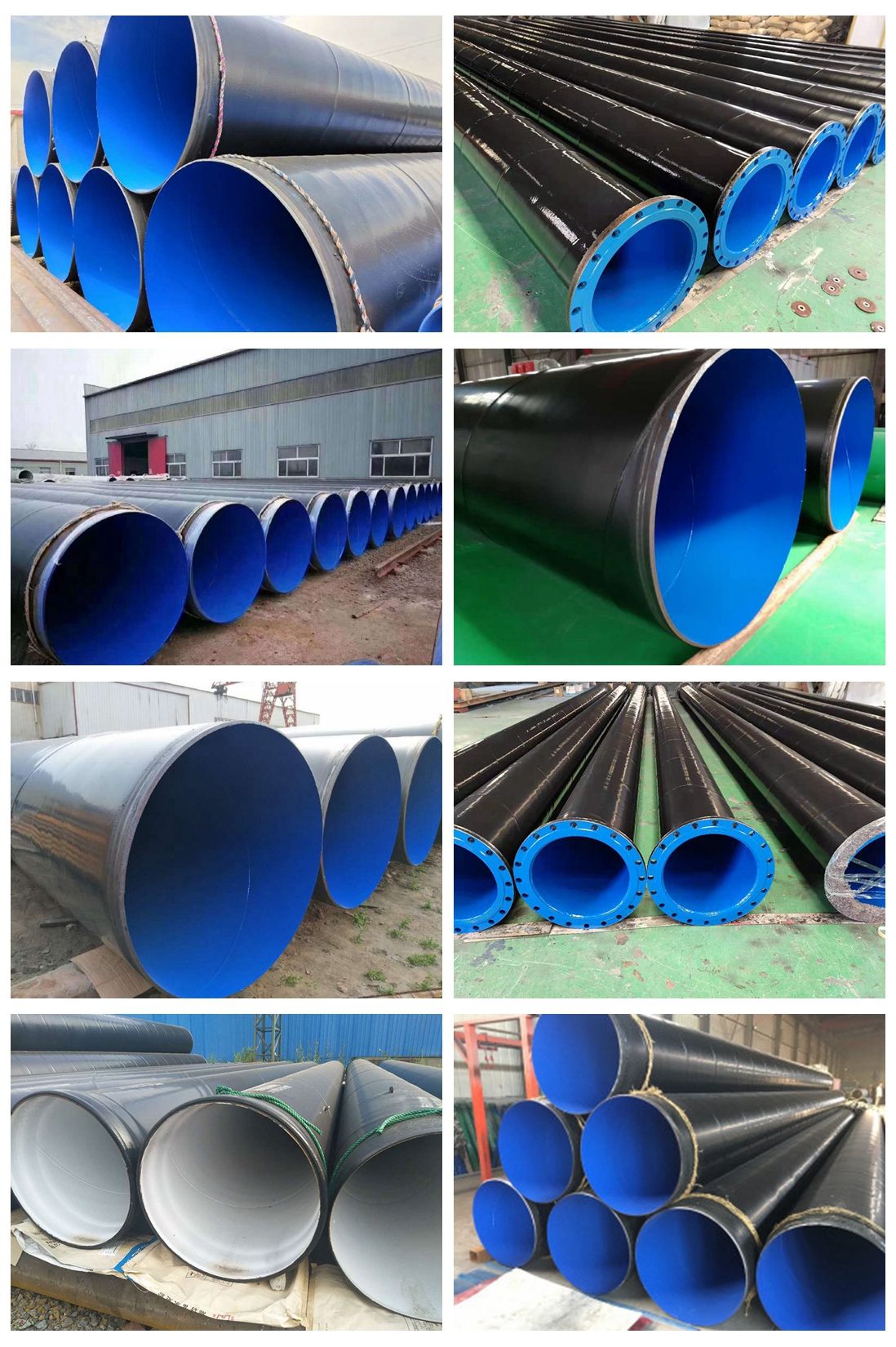

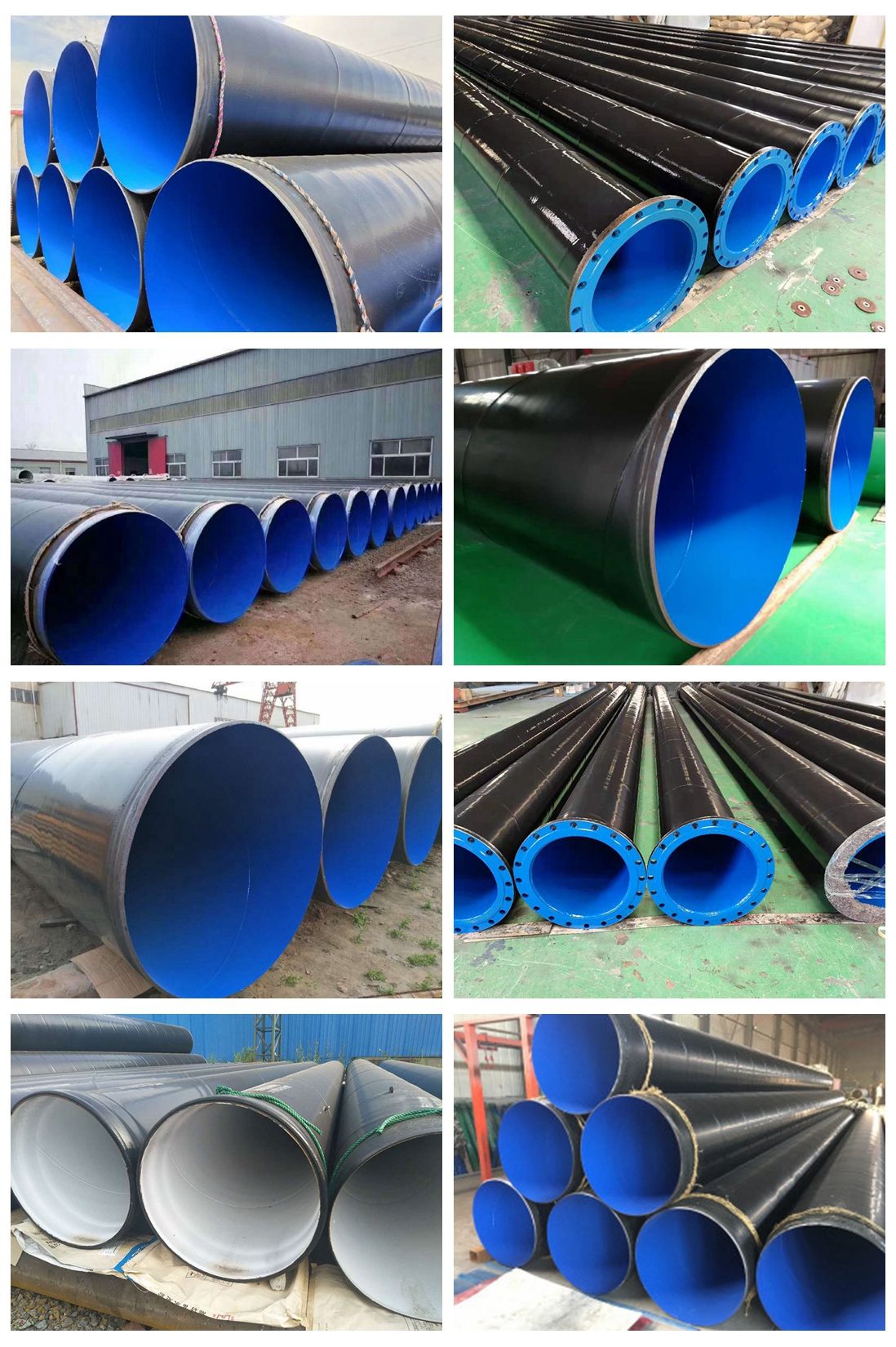

Outer PE inner EP plastic coated composite steel pipe

The outer PE inner EP plastic-coated steel pipe is professionally sold. There is no caliber limit for the coated (rolled) plastic-coated composite steel pipe. The thickness of the lining can also be selected arbitrarily. According to the conditions of the corrosive medium, different lining thicknesses can be selected, and the length can also reach 6-12 meters; the same The nominal diameter of the coated (rolled) plastic composite steel pipe is generally between 0.5-1mm, the inner surface of the pipe is smooth, not only the friction coefficient is small, but also the wear coefficient is small, the fluid loss in the pipe is small, the conveying flow is large, and energy saving is achieved. In recent years, anti-corrosion spiral steel pipes have been widely used in construction water supply and drainage, drinking water distribution, fire pipelines and other projects. Most of the steel pipes for fire pipelines used hot-dip galvanized steel pipes. Now many communities, hotels, and office buildings have begun to use them. The internal and external epoxy powder-coated anti-corrosion steel pipes are used as the material of fire-fighting pipes, which are beautiful and durable, and have become the main products of emerging industries in the 21st century. The outer PE inner EP plastic-coated steel pipe is professionally sold. The powder coating of the plastic-coated steel pipe adds flame retardants and modifies the epoxy resin powder. The coating has superior temperature resistance and does not burn or soften in long-term use.

The advantages of outer PE and inner EP plastic-coated steel pipes: epoxy powder anti-corrosion steel pipe paint film is tough and water-resistant, and the paint film is non-toxic. Strong adhesion, good adhesion between paint film and paint film. Excellent anti-rust and water-resistant performance, using excellent anti-rust raw materials to ensure its anti-rust performance. It has good mechanical strength, tough paint film, abrasion resistance and impact resistance. High solid content and thick coating film. The molecular structure of epoxy powder anti-corrosion steel pipe is characterized by the presence of active epoxy groups in the molecular chain. The epoxy groups can be located at the end, middle or cyclic structure of the molecular chain. . Due to the active epoxy groups in the molecular structure, they can be cross-linked with various types of curing agents to form insoluble and infusible polymers with a three-way network structure. At present, the thermosetting powder coatings used in various countries mainly include: epoxy powder coatings, epoxy phenolic powder coatings, polyester powder coatings, and epoxy-polyester powder coatings. Among them, epoxy powder coating is the earliest variety, and it is also the plastic powder coating currently occupied by output. It is widely used in electrostatic spraying process and occupies a very important position in decorative coating; and epoxy phenolic powder coating is relatively High chemical resistance, so it is mostly used for anti-corrosion coating.

Thermoplastic powder coatings currently mainly include: polyethylene powder coatings, polyvinyl chloride powder coatings, polypropylene powder coatings, chlorinated polyether powder coatings, nylon powder coatings, polyphenylene sulfide powder coatings, etc. These thermoplastic powder coatings have their own advantages and disadvantages . Thermosetting plastics have better curing leveling and wetting properties due to their small molecular weight, which enables them to have strong adhesion to the pipe body when coating steel pipes, and enables plastic-coated steel pipes to obtain a smoother plastic film. surface.

Commonly used thermosetting plastics are: epoxy resin, phenolic resin, amino resin, etc. The wall thickness of the coating is between 100 microns and 500 microns, usually 350 microns. Product features 1. Hygienic, non-toxic, non-fouling, non-breeding of microorganisms, ensuring fluid quality 4. Good weather resistance, suitable for harsh environments such as deserts and saline-alkali. Process the pipe thread, and pay attention to cooling during processing; for flange connection, on-site measurement and drawing of single-line processing drawings of the pipeline can be performed, and after processing, coating and plastic lining, it can be transported to the site for installation; non-coated, plastic-lined steel pipes and pipes can be used on site. Pipe fittings, flange welding, assembling pipes, then dismantling for coating and plastic lining processing, and then transporting to the site for installation; priority should be given to finished grooved plastic-coated pipe fittings; grooves should be grooved by rolling groove machine, pay attention to groove depth should comply with the relevant standards.

English

English Español

Español