Pipe Type: FBE (Fusion Bond Epoxy) Coated Pipe, Epoxy Coated Carbon Steel Pipe,Single-layer Anti-corrosion Epoxy Powder Pipe,Double Layer FBE Coating Pipes

Specification: Outer diameter: 20mm~3600mm

Wall thickness: 1mm~80mm

LENGTH: Random Length, Fixed Length, SRL, DRL

Application: Used for natural gas, petroleum, water & sewage, and pipe systems

Coating Standard: DIN 30670, DIN 30671, DIN 30678, SY/T0413-2002 CAN/CSA-Z245.21etc.

Pipe Type: Submerged Arc Welded (LSAW/SSAW), Electrci Resistance Welded

Surface: One Layer / Double Layer FBE anti-corrosive coating powder (200um~800um)

Ends: Plain,Beveled, Thread With Couplings Or Sockets; Plastic Caps And Steel Rings Can Be Provided if possible

Packing: Waterproof Paper wrapped, Steel Strips bundled, two tags on each bundle

FBE coating steel pipe is fusion bonded epoxy coating steel pipe.It is a kind of external heat resin used for pipes.With a form of dry powder at thickness 400-600 microns on to the heated surface of pipe.Once the FBE coated on the pipe surface,the FBE film provides an extremely hard surface with great adhesion to the surface of pipe.The FBE layer in a even form and have good resistance to the chemical reaction.

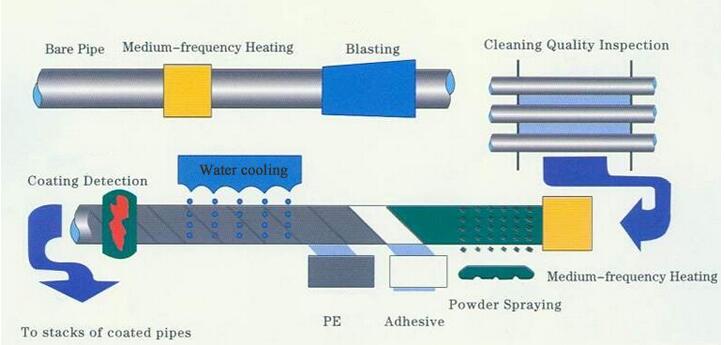

The steel pipes are treated by shot blasting and intermediate frequency preheating before painting, and then the epoxy powder coating is sprayed on the surface of the heated pipe products by electrostatic spraying method, which is fused and bonded on the surface of the steel pipe and solidified to form a coating. FBE coating is usually one – step film – forming structure.

Features of fusion bonded epoxy(FBE) coating steel pipes:

- FBE coating is corrosion resistant and chemical resistant

- FBE coating has strong adhesion to steel, film integrity, soil stress and wear resistance.

- FBE coating increases the life span of steel pipes.

- The FBE coating can be used for external corrosion protection of buried or underwater steel piping installations with operating temperatures of -30~100 °c.

- On the other hand,the defect of the FBE steel pipe is it have poor resistance to mechanical damage and heat and humidity.

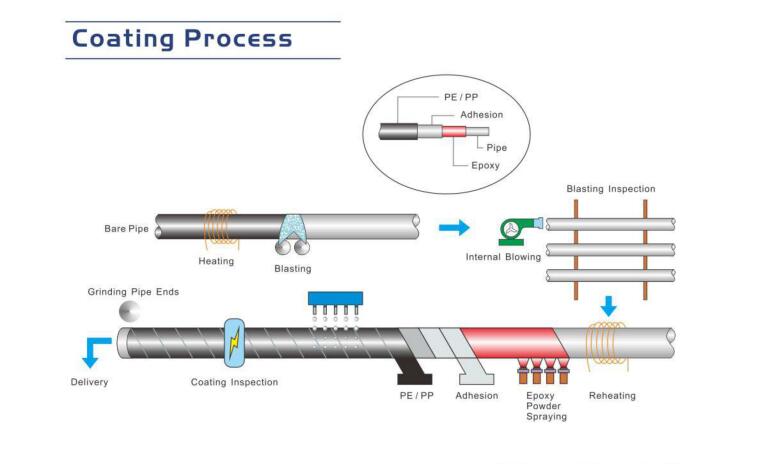

- A three-layer extruded polyethylene coating (3LPE) is composed of extruded, three-layer, anti-corrosive steel pipe coatings.

Single-layer Anti-corrosion Epoxy Powder Pipe

Melting guitar epoxy powder coating:

Coating Material : Epoxy Powder, Adhesion, Polyethylene Or Polypropylene, Cement Inside

Standard: API 5L (PSL1, PSL2); GB/T 9711.1;

Grade: Gr. B, X42, X46, X52, X60, X65, X70, X80; Q235B; Gr. C;

Seam: SAW, SSAW; HSAW

Specifications:

Outside Diameter: 219-2020 MM

Wall Thickness: 5-25MM

Length: 4/6/12/18/21 meters

End: Plain or Bevelled

Surface; Bare or Black Painted or Anti-corrosion, such as 3LPE;

Double Layer FBE Coating Pipes

The double-layer FBE coating system consists of an FBE base coat covering the bare tube surface and a modified FBE top coat. The coating process of the 2 Layer FBE pipe is basically the same as the standard sintering FBE spraying process, except that the layout of the powder spraying chamber and spray gun has changed, without adding complicated equipment. There are two types of spray guns: double powder spraying chamber and integral powder spraying chamber. They are used in the double-layer FBE coating system, such as double powder spraying chamber spraying and integral powder spraying chamber spraying.

The performance characteristics of the double-layer FBE coating system have been proved by laboratory tests and field application tests. The double-layer FBE anti-corrosion system applied to buried steel pipelines has high bonding strength with the substrate, high resistance to cathodic peeling, and low water absorption. Good high-temperature resistance. The characteristic of this system is that it combines the higher bonding performance of standard FBE and substrate and the better water permeability resistance of modified FBE.

Types Of Coated Pipes:

FBE Coated Pipe

“FBE Coated Pipe” is a specific kind of “Epoxy Coated Pipe.” It employs a method called Fusion-Bonded Epoxy (FBE) through melt bonding. This creates a strong and lasting coating.

The Fusion Bonded Epoxy (FBE) coating protects pipe surfaces from corrosion. Using double or triple layers of FBE increases resistance to friction and abrasion. In 3-layer PE/PP coating systems, the FBE coating is employed as the priming layer.

In a process conducted at temperatures between 220 and 235°C, electrostatic epoxy powder is sprayed onto the pipe. Upon reaching the hot pipe surface, the epoxy powder melts, forming a uniform epoxy coating on the pipe.

Dual Layer FBE Coated Pipe

Dual-layer FBE is used in various service scenarios. These encompass directional drilling, protection against abrasion for road and river crossings, and the coating of oil, gas, and waterworks pipes.

Similar to the previously mentioned single-layer FBE coating, this coating is applicable across a broad range of outer diameters (ODs), ranging from 3.5″ to 48″.

In most cases, the outer layer prioritizes abrasion resistance. It acts as a safeguard against erosion.

2LPE Coated Pipe

Two-layer extruded polyethylene coating (2LPE) refers to a two-layer pipeline protection system. Mastic-based adhesives and polyethylene copolymers are used in the two-layer construction. This provides excellent corrosion prevention, especially at high temperatures.

2LPP Coated Pipe

The 2LPP System is a multi-layer powder coating system comprising two functional components. This anti-corrosion system consists of a layer of polypropylene followed by a high-performance fusion-bonded epoxy (FBE) coating.

3PE Coated Pipe

To address the drawbacks of individual anti-corrosive methods, the three-layer polyethylene (3PE) anti-corrosive coating integrates the characteristics of epoxy powder FBE and the two-layer PE coating.

The principal anti-corrosive agent is FBE. PE primarily protects FBE (mechanical damage resistance) and has excellent water penetration resistance.

The three-layer polyethylene coating technique imparts exceptional mechanical properties to meet the requirements of the coating material, allowing it to function at temperatures up to 50°C (for low- and medium-density polyethylene) or 70°C (for high-density polyethylene).

3PP Coated Pipe

The three-layer polypropylene (3PP) anti-corrosive coating consists of an initial layer of epoxy powder, an intermediary layer of binder, and an outer layer of PP (polypropylene) jacket.

The 3PP incorporates all of the benefits of the 3PE while significantly improving its temperature performance in service. The predominant use of 3PP coating is as an anti-corrosion layer for pipelines carrying high-temperature media. Additionally, it serves as a corrosion-resistant layer for pipelines in desert areas with elevated surface temperatures and prolonged exposure to sunlight.

As a result, subterranean water, gas, and oil pipelines have become increasingly popular in places with high surface temperatures and long daylight duration.

English

English Español

Español