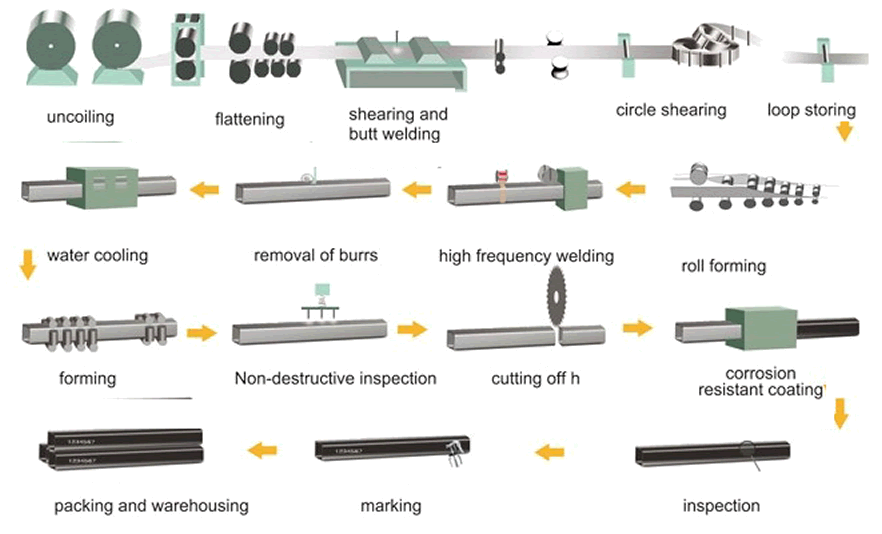

Carbon steel rectangular hollow sections are often abbreviated to “RHS” which is also called structural steel rectangular tube, rectangular steel box section and mild steel hollow rectangular bar. It is manufactured from hot rolled carbon steel strip through a series of successive forming with roller change the rectangular shape and then welded from inside using high frequency welding.

Usually, mild steel rectangular tubes are used maintenance and structural purposes, such as machinery manufacturing, construction industry, metallurgical industry, agricultural, vehicles, agricultural greenhouses, automobile industry, railway, highway guardrail, container frame, furniture decoration and structural steel.

Our factory can offer different manufacturing standards of rectangular hollow section, like GB/T6725, GB/T6728, ASTM A500, EN10219, EN10210, JISG3466, EN10219, ASTMA36, AS/NZS/1163 or customized available Steel Grade: SPA-H, SPHC, ASTM A500 grade A, ASTM A500 grade B, ASTM A500 grade C, Q235B, Q345B, Q345E, Q420, Q450, Q460, QSTE500TM, BC550, BS600MC, BS700MC, A36, SS400, S355J0H, S355J2H, S235JR etc.

In addition, our factory can also provide our clients with hot dipped galvanizing process with various kinds of sizes from 30x20mm (height range X width range) to 600mm x 800mm (height range X width range), wall thickness range from 1mm to 30 mm.

Kindly see the following size table for further information and if you do not find the size your needed, please contact us to customize your size and get the latest price.

Rectangular Hollow Section Steel Tube Size:

OD: 20mm*10mm ~ 600mm*400mm

Pipe Standard:ASTM A53, ASTM A500,BS EN 10219,JIS G 3466, ASTM A513, ASTM A36;S235JR,S355JR,Q235,St37,St37-2,St52,SS400, STK500,

Furface:Black bared ,can be galvanized,oiled,painted,powdered.

Packing:Waterproof plastic bag,bundle with strip

Application:Widely used in furniture,interior decoration, structure

Surface:Black bared ,can be galvanized,oiled,painted,powdered.

Packing:Waterproof plastic bag,bundle with strip

Cold Formed Rectangular Hollow Section Specification

Standard : BS EN 10219 - Cold Formed Welded Structural Hollow Sections of Non-alloy and Fine Grain Steels

RHS Sizes: 40mm*20mm - 240*120mm

Wall Thickness : 1.6mm-16.0mm

Length : 6000-14000 mm

Type : Seamless/ Welded / ERW

Dimensional Tolerances : Thickness : (All sizes +/- 10%)

Packing : In bundles, Anticorrosion heat preservation, Varnish coating, Ends can be bevelled or rectangular cut, End Capped Certification & supplementary test, Finishing & Identity Mark

Available Grades : S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355J2+N, IS 4923 / ASTM A500 / As Per Requirement

Surface Protection: Black (Self Coloured uncoated), Varnish/Oil Coating, Pre-Galvanized, Hot Dip Galvanized

Hot Finish Rectangular Hollow Section Specification

Standard : BS EN 10210 - Hot Finished Structural Hollow Sections of Non-alloy and Fine Grain Steels

Sizes : 300x200 mm

Wall Thickness : 0.5mm - 25mm

Length : 6000-14000 mm

Type : Seamless/ Welded / ERW

Dimensional Tolerances : Thickness : (All sizes +/- 10%)

Packing : In bundles, Anticorrosion heat preservation, Varnish coating, Ends can be bevelled or rectangular cut, End Capped Certification & supplementary test, Finishing & Identity Mark

Available Grades : S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355J2+N, IS 4923 / ASTM A500 / As Per Requirement

Surface Protection: Black (Self Coloured uncoated), Varnish/Oil Coating, Pre-Galvanized, Hot Dip Galvanized

SS Rectangular Hollow Section Specification

Specifications : ASTM A554 / ASME SA554

Sizes : 10mm x 20mm to 150 x 300mm, other non standard sizes available on request

Wall Thickness : 0.5mm - 25mm

Length : Up to 6 meters, custom cut lengths

Type : Seamless/ Welded / ERW

Packing : In bundles, Anticorrosion heat preservation, Varnish coating, Ends can be bevelled or rectangular cut, End Capped Certification & supplementary test, Finishing & Identity Mark

Available Steel Grades : 304, 304L, 304H, 316, 316L, 316H, 316Ti, 321, 321H, 310S, 202, 409, 409L / As Per Requirement

Finish : 2B, No.1 Pickled Finish, No.4 finish, BA Finish, No.8 Mirror Finish, Electr

English

English Español

Español