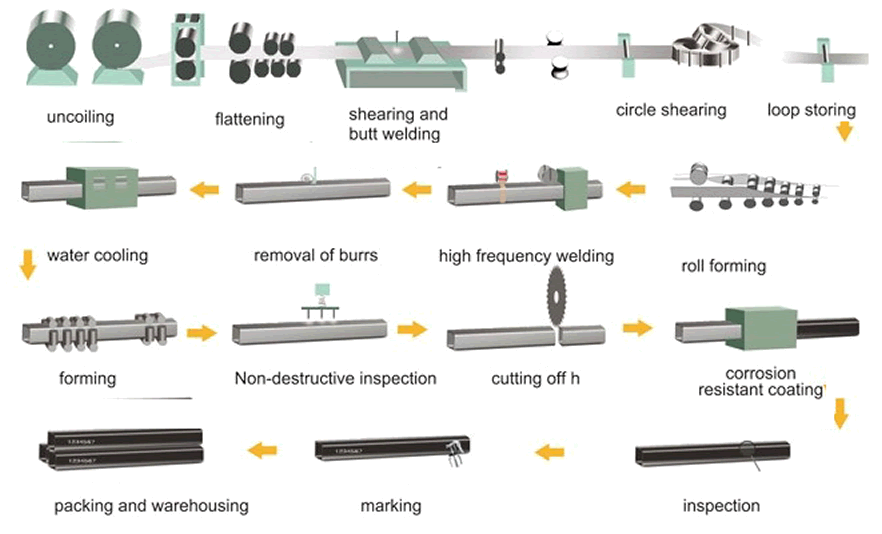

Square hollow section is often contracted to SHS, and also was called structural square steel tubes, structural square tube, structural SHS, structural square hollow box section, structural square hollow section, cold formed steel square tube, and mild steel square tube which is a kind of structural hollow section. It is manufactured by custom steel strip or custom steel sheet through process of cold formed directly into square shape and then in high frequency welding process to finish.

Our factory can offer following steel grade and manufacturing standards for square hollow section, GB/T6725, GB/T6728, ASTM A500, EN10219, EN10210, JISG3466, EN10219, ASTMA36, AS/NZS/1163 or customize, available Steel Grade: SPA-H, SPHC, ASTM A500 grade A, ASTM A500 grade B, ASTM A500 grade C, Q235B, Q345B, Q345E, Q420, Q450, Q460, QSTE500TM, BC550, BS600MC, BS700MC, A36, SS400, S355J0H, S355J2H, S235JR or customize, in addition, our factory can also provide hot dipped galvanized square hollow section and hot dipped galvanized square steel tube which was widely used in machinery manufacturing, construction industry, metallurgical industry, agricultural, vehicles, agricultural greenhouses, automobile industry, railway, highway guardrail, container frame, furniture decoration and structural steel.

Hot dipped galvanized square hollow section, galvanized square steel tube,galvanized square steel hollow box section for your reference.

Cold Formed Square Hollow Section Specification

Standard : BS EN 10219 - Cold Formed Welded Structural Hollow Sections of Non-alloy and Fine Grain Steels

SHS (Square Hollow Sections) Sizes : 20*20mm-600*600mm

Wall Thickness : 0.5mm - 25mm

Length : 6000-14000 mm

Type : Seamless/ Welded / ERW

Dimensional Tolerances : Thickness : (All sizes +/- 10%)

Packing : In bundles, Anticorrosion heat preservation, Varnish coating, Ends can be bevelled or square cut, End Capped Certification & supplementary test, Finishing & Identity Mark

Available Grades : S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355J2+N, IS 4923 / ASTM A500 / As Per Requirement

Surface Protection: Black (Self Coloured uncoated), Varnish/Oil Coating, Pre-Galvanized, Hot Dip Galvanized

Hot Finish Square Hollow Section Specification

Standard : BS EN 10210 - Hot Finished Structural Hollow Sections of Non-alloy and Fine Grain Steels

Sizes : 20*20mm-600*600mm

Wall Thickness : 0.5mm - 25mm

Length : 6000-14000 mm

Type : Seamless/ Welded / ERW

Dimensional Tolerances : Thickness : (All sizes +/- 10%)

Packing : In bundles, Anticorrosion heat preservation, Varnish coating, Ends can be bevelled or square cut, End Capped Certification & supplementary test, Finishing & Identity Mark

Available Grades : S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355J2+N, IS 4923 / ASTM A500 / As Per Requirement

Surface Protection: Black (Self Coloured uncoated), Varnish/Oil Coating, Pre-Galvanized, Hot Dip Galvanized

SS Square Hollow Section Specification

Specifications : ASTM A554 / ASME SA554

Sizes : 20*20mm-400*400mm

Wall Thickness : 0.5mm - 25mm

Length : Up to 6 meters, custom cut lengths

Type : Seamless/ Welded / ERW

Packing : In bundles, Anticorrosion heat preservation, Varnish coating, Ends can be bevelled or square cut, End Capped Certification & supplementary test, Finishing & Identity Mark

Available Steel Grades : 304, 304L, 304H, 316, 316L, 316H, 316Ti, 321, 321H, 310S, 202, 409, 409L / As Per Requirement

Finish : 2B, No.1 Pickled Finish, No.4 finish, BA Finish, No.8 Mirror Finish, Electropolished Square Pipes

Delivery Condition: Bright Annealed, Polished or Annealed and Pickled

English

English Español

Español