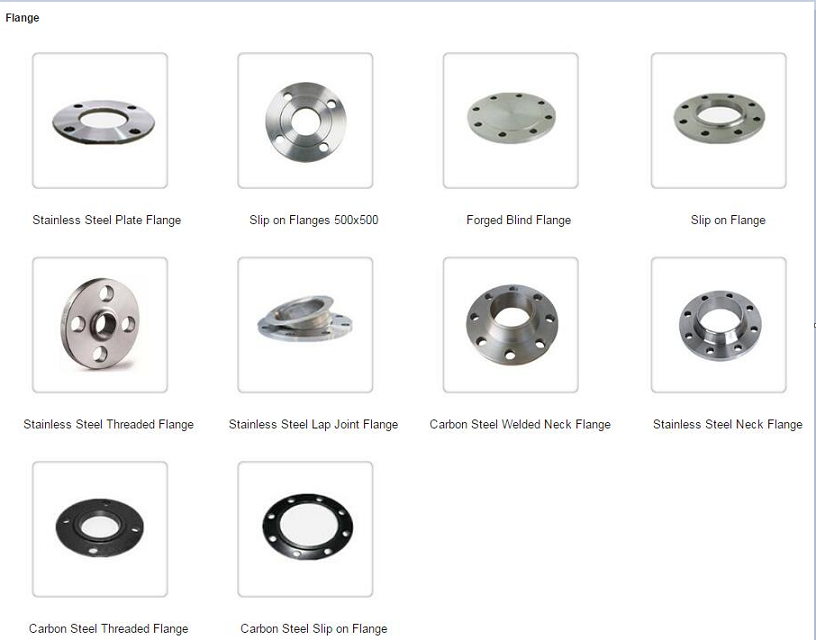

Type:Weld neck flange, slip on flange, blind flange, threaded flange, socket weld flange, plate flange, spectacle blind, LWN, Orifice flange, anchor flange etc.

Size: OD: DN15- DN2000 (1/2''- 80'') and customized

Type: welding neck, slip on, blind, socket welding, threaded, lap-joint

Pressure: 150#, 300#, 600#,900#,1500#, 2500#,PN10,PN16,PN25,PN40;JIS 5K,JIS 10K;

Material: carbon steel A105, C22.8, S235, S235JR, P235GH,SS400,37.2

Stainless Steel :F 304, 304L, 304H, 316, 316Ti, 316H, 316L, 316LN, 309S, 309H, 310S, 310H,317, 317L, 321, 321H, 347, 347H, 201, 202, 904L,1.4301, 1.4404

ASTM A234 WP1/5/9/11/12/22/91,DEPLEX S31803/F51,S32750/F53

Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS3150

Other materials:alloy steel;copper steel;Titanium steel;Aluminium steel etc

Coating: Rust-proof oil, cold and hot galvanize and customized

Packing: sea worthy plywooden case, wooden pallet

English

English Español

Español