Product Type:Carbon Seamless Mechanical Tube,Seamless Mechanical Tube,Seamless Alloy Steel Mechanical Tube

Size:

Outer Diameter : 10.3-762mm

Wall Thickness: 6-35mm

Length:5.8/6/11.8/12m

Standard: ASTM A53, ASTM A519, ASTM A500, ASTM

A252, JIS G3441/G3445,EN 10210/10297

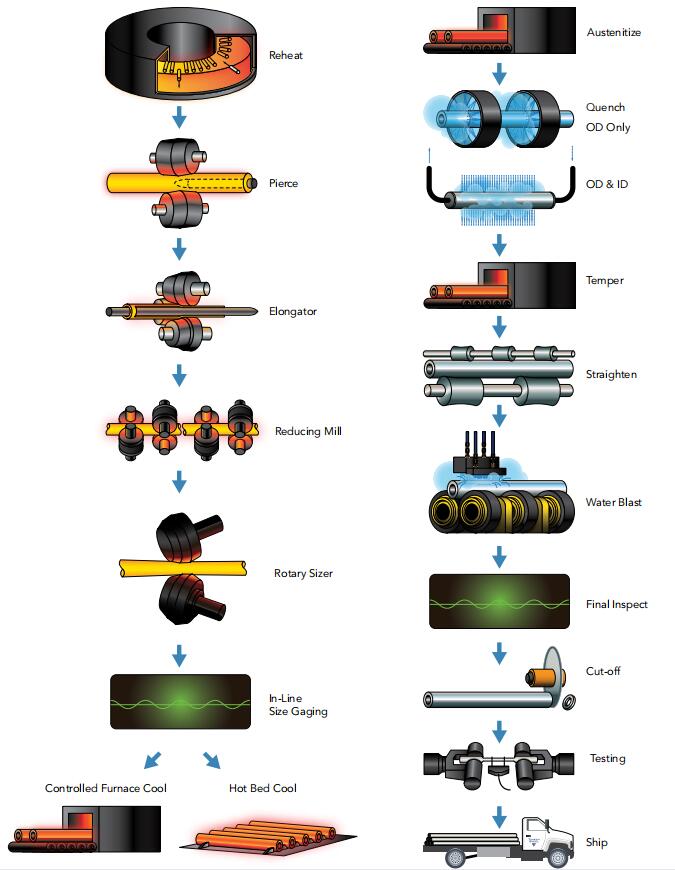

Seamless mechanical tubing is manufactured to meet your specific application requirements.

Seamless mechanical tubing is furnished in both cold-drawn and hotfinished form in a wide range of sizes, from 1.375" to 7.750" OD and from 0.188" to 1.625" wall thickness, as shown on the chart to the right.

Seamless mechanical tubing

A-519

D.O.M mechanical tubing

A-513 T5

E.R.W mechanical tubing

A-513 T1 or T2

MECHANICAL TUBING APPLICATION

Tubing used for mechanical and light gauge structural applications. Mechanical tube is produced to meet specific end use requirements, specifications, tolerances and chemistries. This allows for more specific property uniformity throughout the tube compared to standard pipe or tube. While Mechanical tube can be produced to standard specifications when requested, it is often produced to “typical” properties that focus mainly on the yield strength for a precise size and wall thickness. In some applications with severe forming, yield strength may not even be specified and the mechanical tube is produced to be “fit for use”. Mechanical tubing encompasses a wide range of both structural and non-structural applications.

MECHANICAL TUBING TYPE

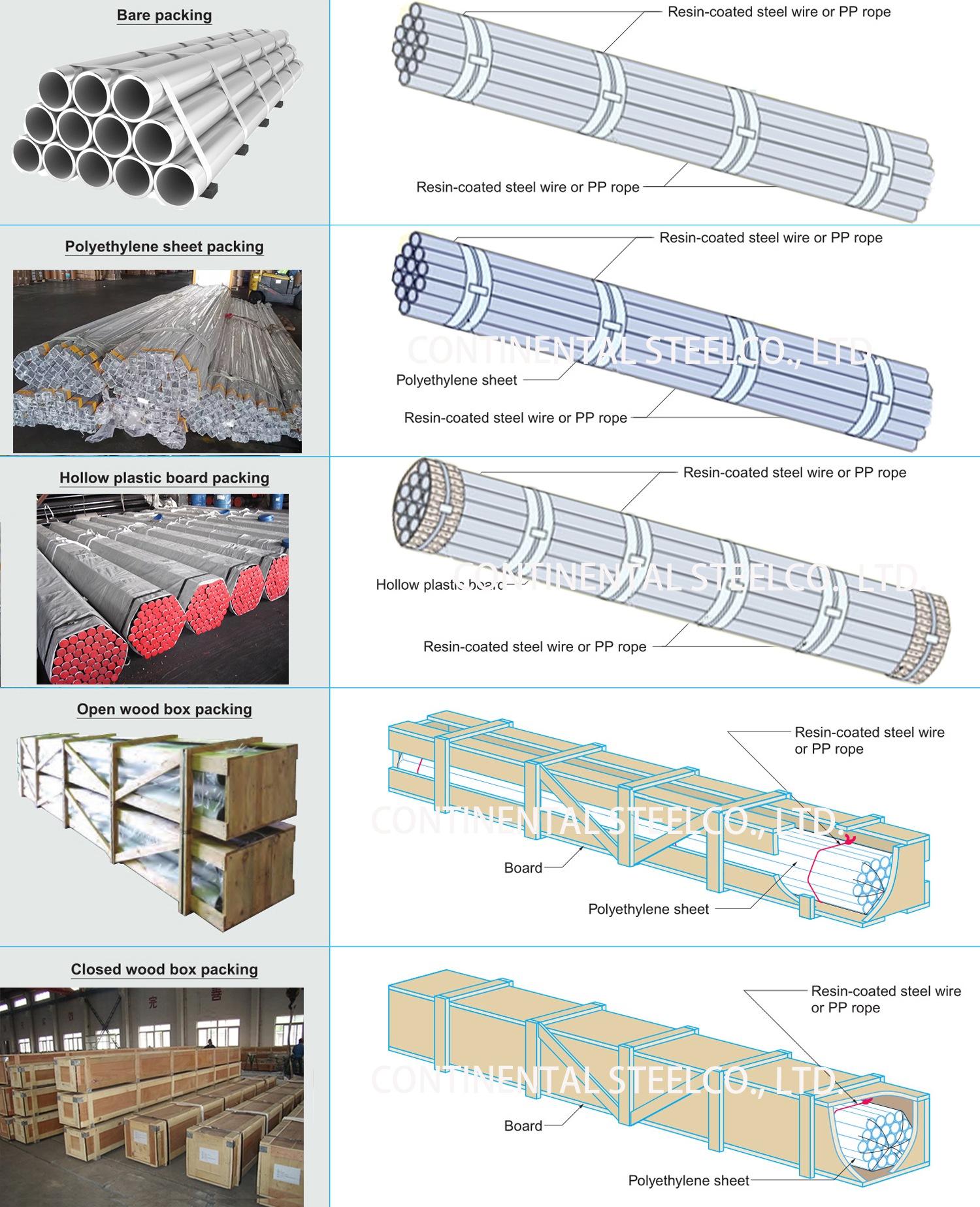

Mechanical tubing is manufactured to typical mechanical tube properties in accordance with ASTM A513 and ASTM A519 specifications. Some of the most common types of mechanical tubing are Drawn Over Mandrel tubing (DOM), Hot Rolled/Finished Seamless tubing (HRS), Cold Drawn Seamless tubing (CDS), Hot Rolled or Cold Rolled Electric Weld tubing (HREW/CREW), and 4140 Alloy tubing. Mechanical tubing is not limited to these specifications and can be produced to exact customer requirements when appropriate. Mechanical products are ordered to a specific outside dimension (OD) and “gauge” or wall thickness or by outside dimension (OD) and inside dimension (ID). Additionally, most mechanical tubing can be available in galvanized as well upon request.

English

English Español

Español