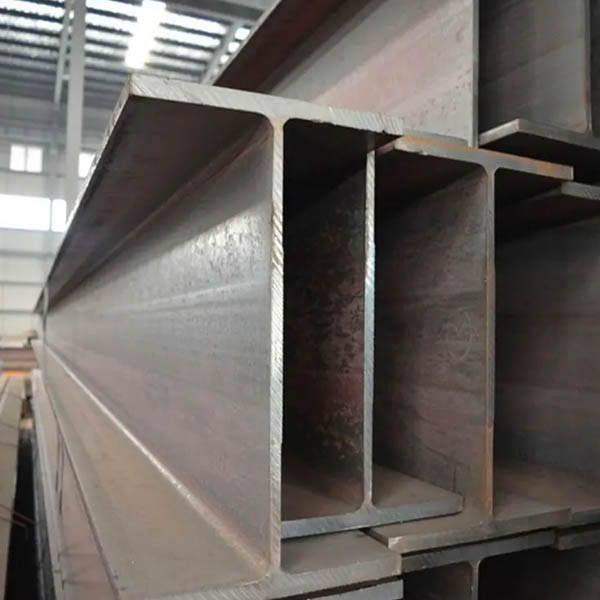

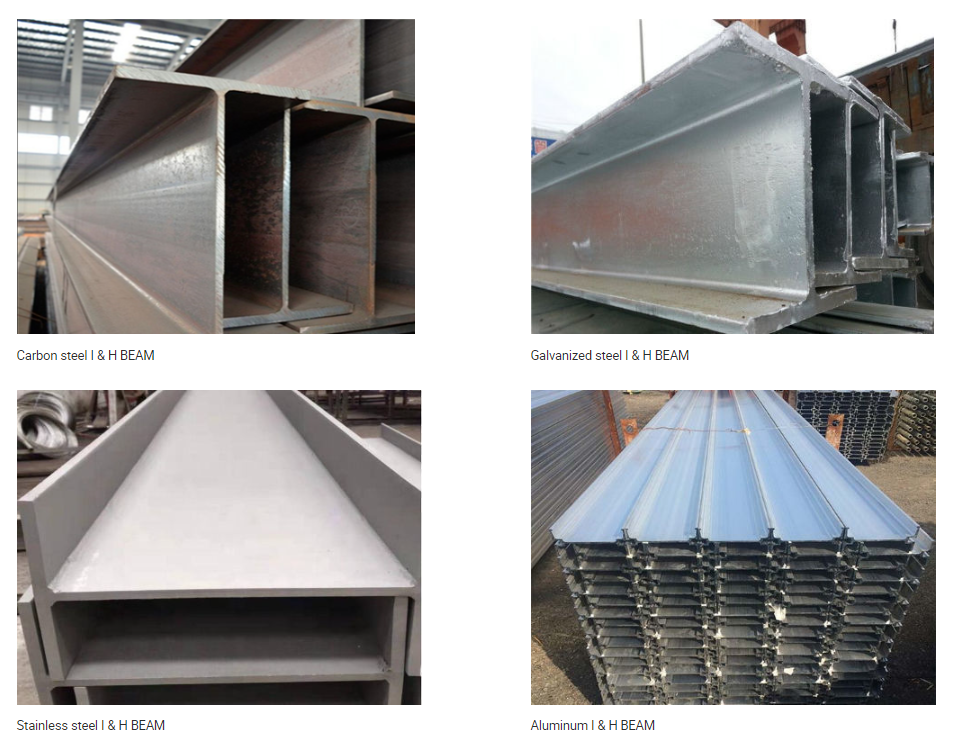

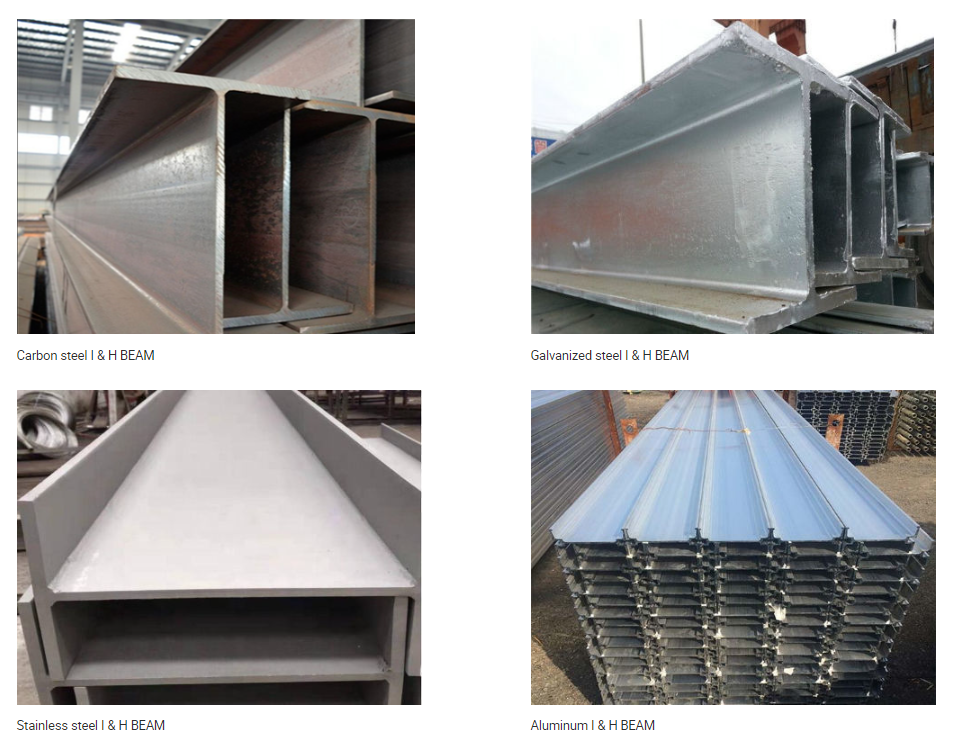

Pipe Type:Structural H Beam,H Beam ,H section,Carbon Steel H-beam,Stainless Steel H-beam,

Galvanized H Beam,Aluminum H Beam,Alloy H Beam,Wide Flange Beam,High-Spec H-Beams,Patterned H-Beams

Size:100*50-700*300mm

Web Thickness:5-16mm

Web Width:50--300mm

Flange Thickness:4.5-23mm

Flange Width:50-400mm

Length:1-12m or as customer request

Standard:AISI,ASTM,DIN,JIS,GB ,JIS,SUS,EN,BS ISO.etc

Shape:H Channel/I Channel

Technique:Hot rolled/Cold Rolled/Galvanized

Edge:Mill Edge/ Silt Edge

Surface Treatment:Hot Dip Galvanized, Painting or Black.

Application:Construction,Decoration,Ship,Medical Equipment,Machinery,Mechanical&manufacture,Steel structure,Shipbuilding,Bridging, Automobile chassis

Steel Grade:

1015,1020,1035,1045,1055,1060,1213,1140,1215,9255,9262,1039,1025,1335,1330,1050,1095,

4520,2515,3135,3415,3310,9840,8620,8740,4340,5015,5132,5140,5115,5155,4130,4137,4135,4140,

4142,6150,Ck10,Ck15,Ck22,Ck25,Ck30,Ck35,Ck40,Ck45,Ck50, 30Mn4,40Mn4 12Cr1MoV Cr5Mo

15CrMo 30CrMo 40CrMo 20SiMn 12Cr1MoVG 20CrNiMo 15CrMoG A3642CrMo 40CrNiMoA 50CrV

Stainless steel H-beam:

Length:1-12m or as customer's request

height:100-1000mm

Width:100-407mm

Thickness:4.0mm-35mm

Tolerance:±0.05mm

Standard:AISI,ASTM,DIN,JIS,GB ,JIS,SUS,EN,etc

Technique:Hot rolled / cold rolled

Surface Treatment:No.1/No.3/No.4/HL/1D/8K

Material:201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S,309S, 410, 410S,420, 430, 431, 440A,904L

Application:Mechanical&manufacture,Steel structure,Shipbuilding,Bridging, Automobile chassis

Carbon Steel H-beam:

Height:100-900mm

Width:50-400mm

Web thickness:5-30mm

Flange thickness:7-40mm

Standard:ASTM,AISI,JIS,DIN,EN,BS

Processing Type:Cutting, bending,stamping,welding,cnc machining

Cutting Type :Laser cutting;water-jet cutting;flame cutting

Surface Treatment:1),Bared2),Black painted (varnish coating)3),Galvanized4),With oiled-covered

Application:Construction,Decoration,Ship,Medical Equipment,Machinery,etc

Technique:Hot Rolled Edge:Mill Edge/ Silt Edge

Grade:1015,1020,1035,1045,1055,1060,1213,1140,1215,9255,9262,1039,1025,1335,1330,1050,1095,

4520,2515,3135,3415,3310,9840,8620,8740,4340,5015,5132,5140,5115,5155,4130,4137,4135,4140,

4142,6150,Ck10,Ck15,Ck22,Ck25,Ck30,Ck35,Ck40,Ck45,Ck50, 30Mn4,40Mn4 12Cr1MoV Cr5Mo

15CrMo 30CrMo 40CrMo 20SiMn 12Cr1MoVG 20CrNiMo 15CrMoG A3642CrMo 40CrNiMoA 50CrV

English

English Español

Español