Application:Fluid Pipe

Outer Diameter:25-800mm

Thickness:5 - 25 mm

Standard:ASTM, ASTM A106-2006

Grade:Q235, Q195-Q345

Special Pipe:carbon steel pipe

Processing Service:Bending, Welding, Decoiling, Punching, Cutting

Shape:30,60,90degree elbow

Connection:Flange or welded

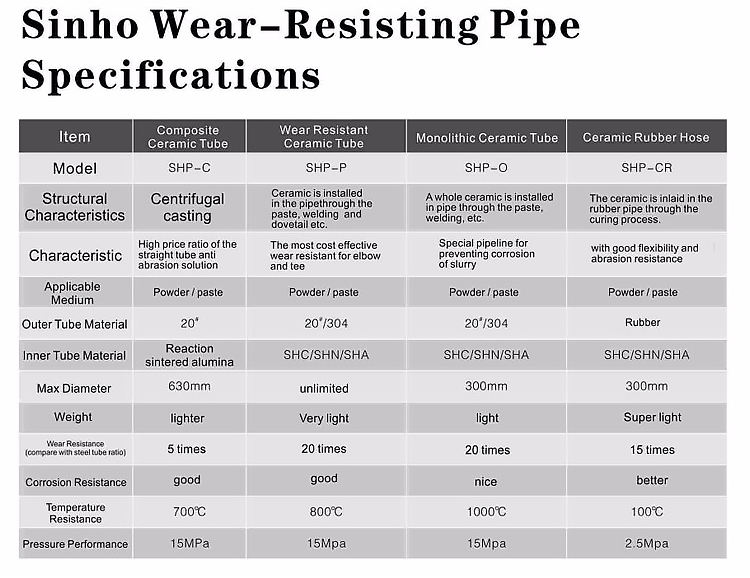

Ceramic thickness:3-50mm

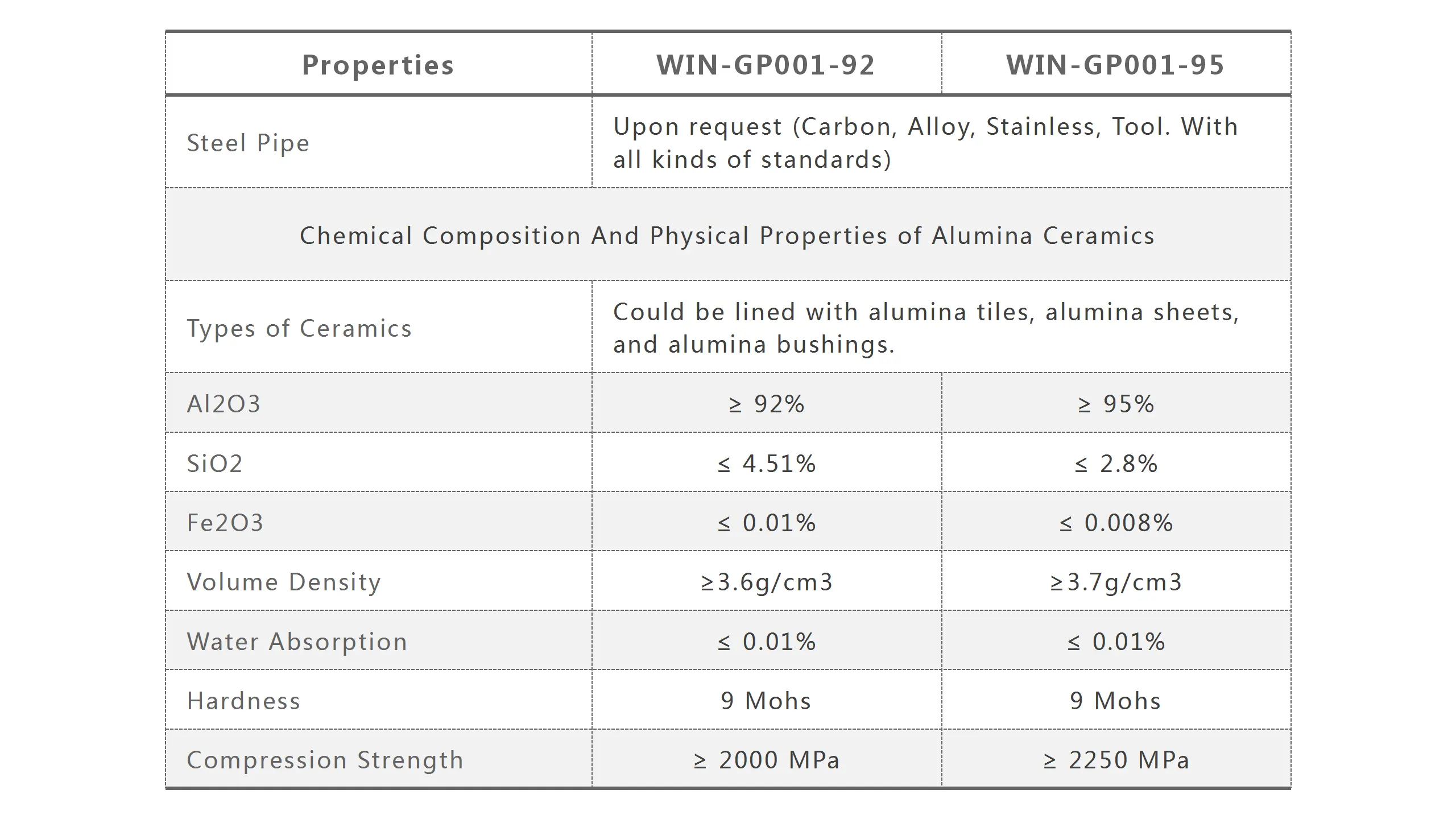

Alumina ceramic hardness:MOHS 9Application:Fluid Pipe

Paint:Anti corrosive paint

Alumina ceramic content:92%,95%

Ceramic density:3.6; 3.7 g/cm3

Use temperature:-50°C~1000°C;Paste: less than 300°C.Welding is not higher than 600°C .dovetail

below 800°C

Feature :

Wear resistance/Corrosion resistance/Good temperature resistance/Smooth inner wall/Ceramic staggered joint installation/Light weight/Easy to assemble

Application range:Widely used in metallurgy, mining, electricity, coal, petrochemical and other industries, gas solid, liquid solid conveyor system, especially for the elbow, three links, such as wear very serious occasions:Exhaust gas treatment of limestone conveying of pulverized coal fly ash treatment powder conveying conveyor Grain conveying slag conveying slag conveying cement conveying river sand conveying

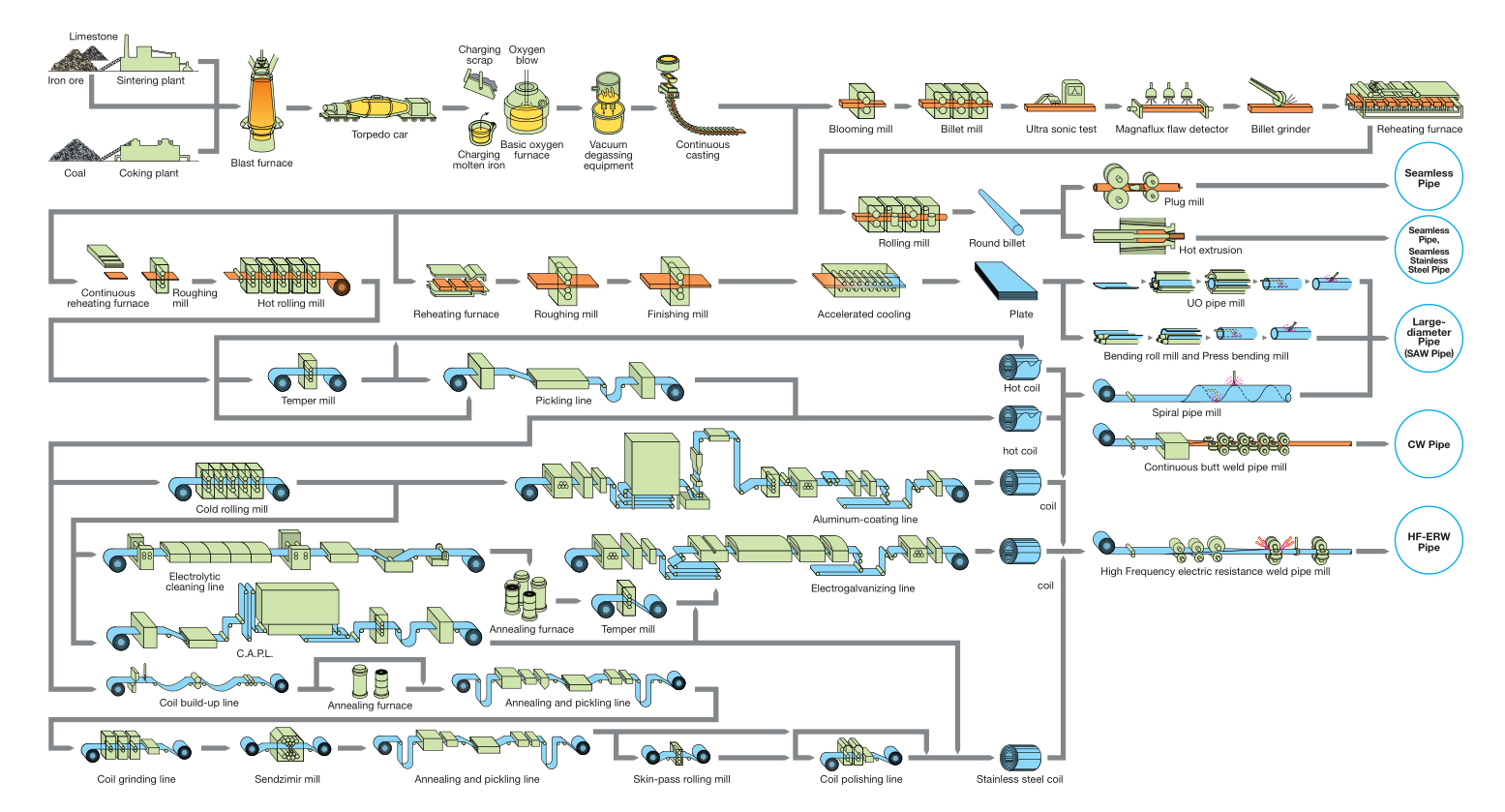

Ceramic wear-resistant pipe Because the pipe has wear-resistant, corrosion-resistant and heat-resistant properties, it can be widely used in electric power, metallurgy, mining, coal, chemical industry and other industries. It is an ideal wear-resistant pipe for transporting abrasive granular materials and corrosive media such as sand, stone, pulverized coal, ash and liquid aluminum. (1) SMD wear-resistant ceramic pipe: the aluminothermic centrifugal method is used to organically combine ceramics and metals. The aluminothermic centrifugal method is used to prepare the lined ceramic steel pipe. The high temperature generated by the exothermic reaction itself is used to melt the reaction products and separate under the action of centrifugal force to form the steel pipe lined with alumina ceramics. (2) Self propagating composite pipe: ceramic powder + iron oxide powder + magnesium oxide powder are mixed in proportion (the main component is iron oxide and black), seal both ends of the pipe, add powder, rotate the pipe, conduct electronic ignition, and sinter on the inner wall of the pipe by centrifugal method. (3) Integral calcined ceramic pipe: according to the mold, the ceramic powder is burned into a ceramic pipe, and then combined with the steel pipe. The outer wall of ceramic pipe and the inner wall of steel pipe are assembled by pouring special filler (cement or epoxy resin) inside the steel pipe, and then formed by isostatic pressing.

English

English Español

Español