- HOME

- COMPANY

-

PRODUCTS

- Carbon welded steel pipe

- SSAW Carbon steel pipe LSAW Carbon Steel Pipe ERW Carbon Steel Pipe

- Carbon steel Seamelss pipe

- Seamless Steel Pipe Boiler Steel Pipe Seamles Line Pipe Honed Tube Hydraulic cylinder pipe U Tube Heat Exchanger Tube Low temperature pipe Seamless Precision Tubes Carbon Seamless Mechanical Tube

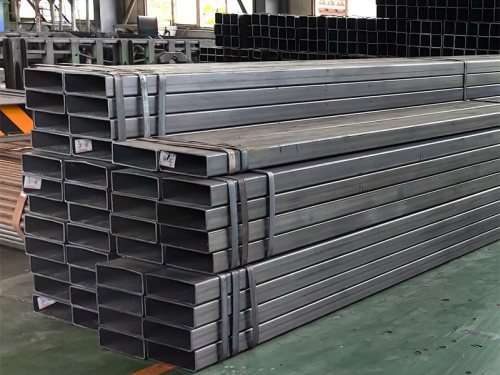

- Steel Hollow Section

- Rectangular steel Pipe Square steel pipe Stainless Hollow Section Carbon Hollow Section

- Stainless Steel Products

- Stainless Steel Coil Stainless Steel Rod/Bar Welded Stainless Steel Pipe Seamless stainless steel pipe

- Anti-corrosion coated steel pipe

- Ceramic-lined Pipe Rubber-lined Pipe Concrete Coated Pipe 2PE /3PE coated pipe FBE coated pipe Galvanized steel pipe

- Alloy steel pipe

- Aluminum steel pipe Copper steel pipe Aluminium Brass Pipe Finned steel tube Titanium alloy pipe Hastelloy alloy pipe Nickel-Copper Alloy Pipe Nickel Alloy pipe Alloy Steel Pipe

- OCTG

- Tubing Pipe Casing Pipe Sucker rod Pup Joint Tubing and Casing Coupling Drill Collars Drill Pipe Screen Pipe

- Steel Profile

- Steel Sheet Pile Angle steel Channel Steel I-Beam H Section

- QUALITY

- SERVICE

- PROJECTS

- BLOGS

- CONTACT

English

English Español

Español