The main function of the oil screen is to prevent sand. The different geological environments (different lithology) of the oil wells lead to different steel grades and types of the screens used.

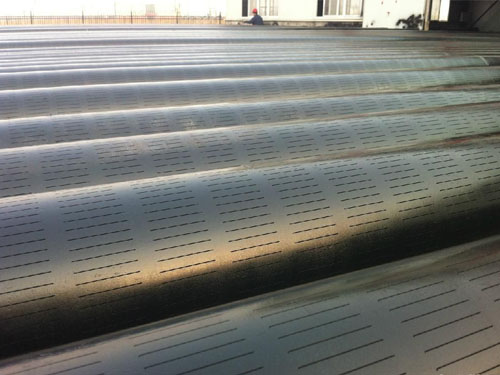

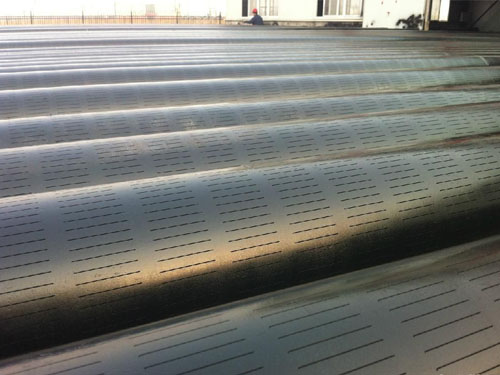

In the oil drilling and production operation, the screen is an important equipment, and it is often used for early completion or oil production and sand control. The most commonly used screen is the wire-wound screen. The manufacturing method of this screen tube is: winding a steel wire of a certain section on the metal liner tube evenly distributed on the surrounding screen rods or openings and welding it firmly, and leaving a certain gap as the screen hole. Although this manufacturing method has been used by many manufacturers in China, there are some problems when this screen goes down well, especially when the strong pressure passes through the curved section of a highly deviated well or a horizontal well, it is unavoidable to contact with the well wall or casing. When the pipe collides, squeezes and rubs, it is prone to the phenomenon of wire disorder, resulting in damage to the screen or deformation of the gap, resulting in the reduction or failure of the completion quality and sand control effect. The slit screen appeared. Due to the superior performance and low price of slotted pipe, it has been highly valued and widely used in major oil fields as soon as it appeared. It can be seen that the appearance of slotted pipe provides material conditions for the development of horizontal wells and sidetracking drilling and the oil exploitation of high sand reservoirs.

English

English Español

Español